Applications

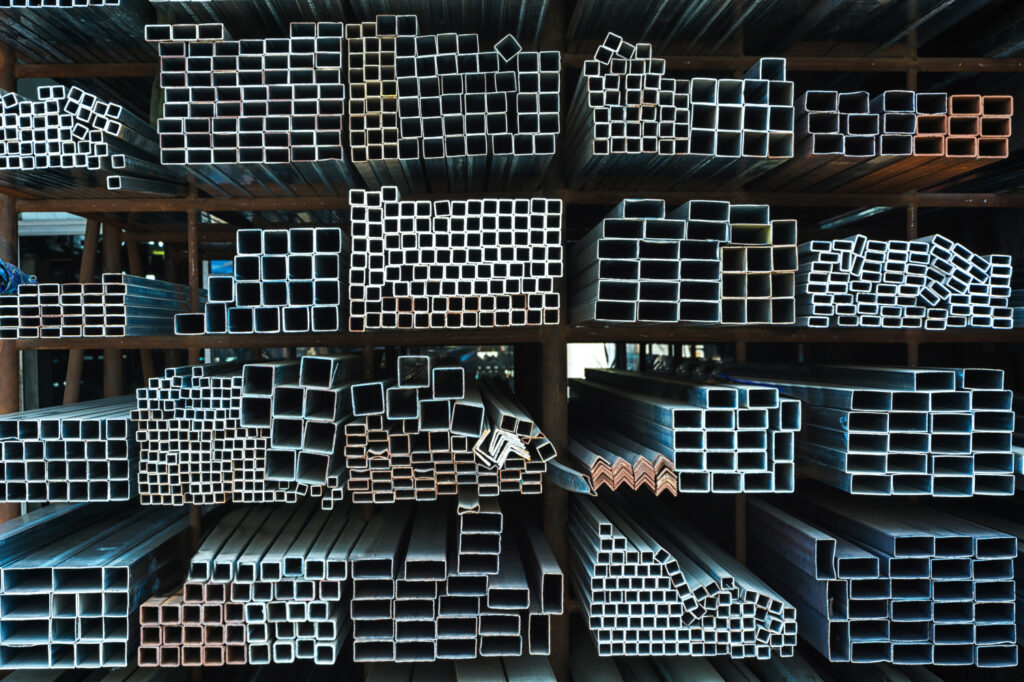

Steel

Sludge Dewatering and Impurity Removal

Yo-Tana Filter presses are essential for the dewatering of sludge and removal of impurities in various processes, contributing to the efficient and environmentally responsible production of steel. Consider a scenario in a steel manufacturing plant where sludge and impurities need to be separated from process water and cooling water systems.

Pain Points

- Sludge Generation: Steel production processes generate sludge containing fine particles and water, requiring effective dewatering methods.

- Impurities in Cooling Water: Impurities in cooling water systems can negatively impact the efficiency of equipment and overall steel production.

Our Yo-Tana filter press solutions

Efficient Sludge Dewatering

Yo-Tana Filter presses efficiently dewater sludge, producing a dry cake that is easier to handle and dispose of.

Impurity Removal

The use of Yo-Tana Filter presses helps in removing impurities from cooling water, contributing to the efficient operation of steel production equipment.

Reduced Environmental Impact

By effectively managing sludge and impurities, Yo-Tana Filter presses minimize the environmental impact of steel manufacturing, promoting sustainability.

Yo-Tana Recommends

- Corrosion-Resistant Materials: Yo-Tana Filter presses constructed with materials resistant to corrosion, as steel manufacturing processes involve water with varying chemical compositions.

- Large Filtration Area: Customization to provide a larger filtration area, accommodating the high volumes of sludge generated in steel production.

- Closed System Design: A closed system design to prevent the exposure of operators to potentially hazardous substances in the sludge and water.

- Automated Controls: Integration of advanced automation controls for precise monitoring and adjustment of filtration parameters, ensuring optimal performance.

- Membrane Yo-Tana Filter Plates: Incorporation of membrane Yo-Tana Filter plates for enhanced dewatering efficiency, especially in processes where a higher degree of dryness in the sludge is required.